What is Diecast Metal?

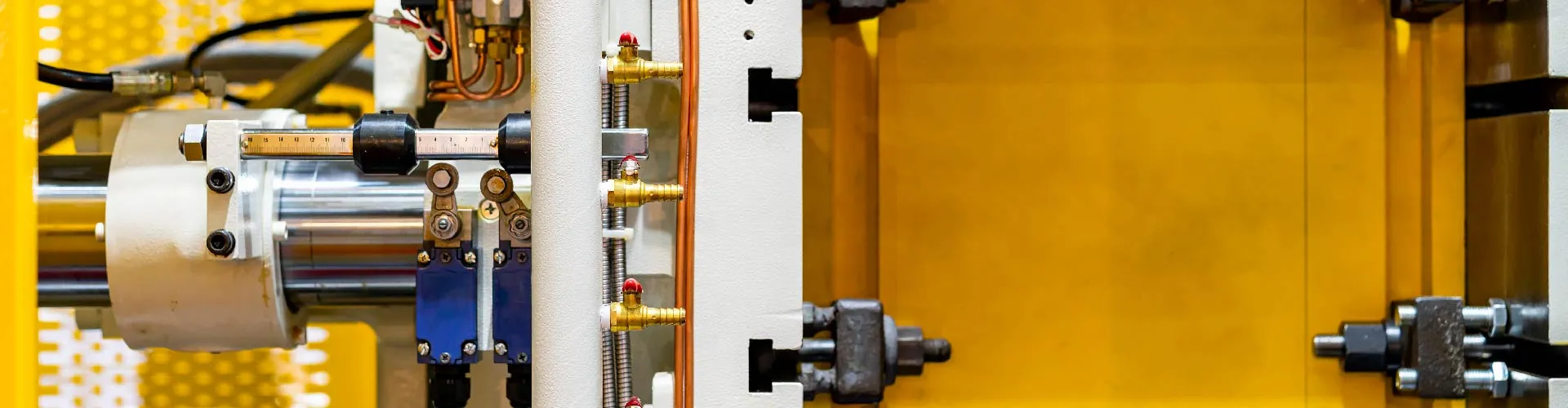

Diecast metal is a manufacturing process that involves injecting molten metal under high pressure into a mold cavity. This process is primarily used to create intricate and complex metal parts with high precision and dimensional accuracy. The die casting process is widely used across various industries due to its ability to produce high volumes of parts quickly and efficiently. Diecast parts are known for their strength, durability, and ability to maintain close tolerances, making them suitable for a wide range of applications. The choice of metal depends on the required properties of the final product, influencing factors such as strength, corrosion resistance, and cost. Understanding diecast metal is the first step in assessing its strength and suitability for different applications.

The Composition of Diecast Metal

The strength of diecast metal is directly related to its composition. Different metal alloys provide different strengths and characteristics. The common metals employed in die casting are zinc, aluminum, magnesium, copper, and lead-tin alloys. Each metal has its unique properties, but the final strength of a diecast part is influenced not just by the base metal but also by the addition of other elements. For example, adding silicon to aluminum can significantly increase its strength and wear resistance. Furthermore, the ratio of the elements and the specific alloy formulation is crucial in determining the final mechanical properties. Understanding these material aspects is crucial in predicting the diecast metal’s overall performance and suitability for specific applications.

Common Materials Used in Diecasting

Several materials are frequently used in die casting due to their desirable characteristics. Aluminum alloys are popular because of their high strength-to-weight ratio, excellent corrosion resistance, and good casting properties. Zinc alloys are often selected for their cost-effectiveness, good dimensional stability, and ability to be cast into very intricate shapes. Magnesium alloys offer a lightweight option with excellent machinability, suitable for applications where weight is a primary concern. Copper alloys, while more expensive, provide superior strength, corrosion resistance, and electrical conductivity. Each material offers a unique blend of properties, with careful consideration necessary to match the alloy to the required application. The material selected directly impacts the metal’s strength, durability, and suitability for the intended application.

Fact 1 Comparing Diecast Metal Strength

Diecast metal strength varies significantly depending on the alloy used. Aluminum alloys, for instance, generally have higher tensile strength compared to zinc alloys. Magnesium alloys, while lighter, often have lower strength properties than aluminum. Copper alloys offer the highest strength among the commonly used diecast materials. Assessing diecast metal strength involves looking at several parameters, including tensile strength and yield strength. These parameters provide insights into the metal’s ability to withstand various types of stress and deformation. Understanding this comparison is crucial for choosing the appropriate alloy for a particular application and for predicting the part’s overall performance.

Tensile Strength

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before it breaks. This is a critical parameter for diecast metal, as it indicates the material’s ability to resist failure under tensile loads. Higher tensile strength means the metal can withstand more stress before fracturing. The tensile strength of diecast metal is highly dependent on the alloy composition and the manufacturing process. For instance, certain aluminum alloys used in die casting can have tensile strengths exceeding 400 MPa, whereas zinc alloys generally have lower tensile strengths. Evaluating the tensile strength is essential in applications where the part will experience significant tensile forces, ensuring the part’s structural integrity and safety.

Yield Strength

Yield strength is another key metric, defining the stress level at which a material begins to deform plastically. This means that beyond the yield point, the metal will experience permanent deformation. A higher yield strength indicates that the material can withstand greater stress before permanent deformation occurs. This is particularly important in applications where the part must maintain its shape and dimensions under load. Like tensile strength, yield strength is also influenced by the alloy composition and manufacturing conditions. Diecast parts with higher yield strengths are often preferred in applications where the part needs to maintain its structural integrity under load without significant deformation. This ensures the part performs correctly and efficiently in its intended application.

Fact 2 Factors Influencing Diecast Metal Strength

Several factors influence the strength of diecast metal, which is pivotal in determining a part’s overall performance and durability. These factors include the alloy composition, the manufacturing process, and the specific die-casting parameters. The selection of alloy plays a crucial role, with each material offering different strength characteristics. Furthermore, the precision of the die-casting process, including temperature control, injection pressure, and cooling rates, also significantly impacts the final mechanical properties. Understanding these factors is essential for optimizing the die-casting process and ensuring that the produced parts meet the necessary strength requirements for their intended applications. Careful control over these parameters guarantees the quality and performance of the diecast components.

Alloy Composition

The specific composition of the metal alloy is a primary determinant of its strength. Alloying elements, such as silicon in aluminum or copper in zinc, can significantly enhance the material’s mechanical properties. For example, adding silicon to aluminum increases its strength and improves its ability to withstand wear. The ratio of elements and the inclusion of trace elements also play a critical role. Modifying the alloy composition allows engineers to tailor the mechanical properties of the diecast metal to meet specific application requirements. The correct alloy composition will ensure that the part performs optimally in its intended application, ensuring reliability and longevity. Careful material selection is, therefore, a key step in the die-casting process.

Manufacturing Process

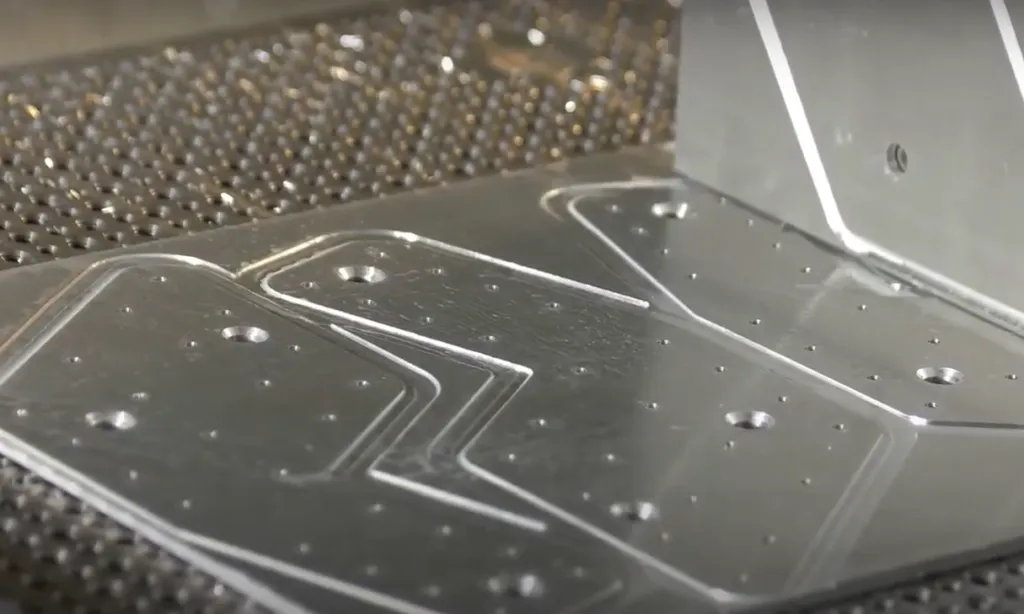

The die-casting manufacturing process directly impacts the metal’s strength. Parameters such as injection pressure, mold temperature, and cooling rates influence the microstructure and the resulting mechanical properties. High injection pressures can help ensure that the molten metal fills the mold cavity completely, minimizing porosity and improving strength. Properly controlling mold temperatures ensures the metal solidifies uniformly, reducing internal stresses that can weaken the part. Efficient cooling rates are critical for controlling the grain size and distribution within the metal structure, also influencing its strength. Any deviations in the manufacturing process can significantly affect the diecast metal’s overall strength and durability, highlighting the importance of precision in die casting.

Fact 3: Diecast Metal Applications

Diecast metal is widely used across many industries, each with unique requirements for material strength and performance. The automotive industry, consumer electronics, and aerospace sectors are among the most significant users of diecast components. These applications demand high precision, durability, and often, complex geometries. The ability to mass-produce parts with high consistency makes die casting an economical solution. Different applications require various types of diecast metals, highlighting the process’s versatility and adaptability. The correct choice of material and process ensures that these components meet rigorous standards and provide reliable performance.

Automotive Industry

The automotive industry extensively uses diecast metal for various components. These include engine blocks, transmission parts, and structural components. The high strength-to-weight ratio of aluminum alloys makes them ideal for reducing vehicle weight, thereby improving fuel efficiency. The precision of the die-casting process allows for the creation of complex geometries and tight tolerances, crucial for engine performance. Diecast metal is essential in producing durable and reliable parts for the automotive industry. The ability to withstand high temperatures, pressures, and stresses is essential in automotive applications, making diecast metal a preferred choice.

Consumer Electronics

Consumer electronics also benefit from diecast metal, frequently found in housings for laptops, smartphones, and other devices. The need for lightweight, durable, and aesthetically pleasing designs makes die casting a suitable choice. The ability to incorporate complex features, such as cooling fins and mounting points, is highly valued in electronic component manufacturing. Aluminum and magnesium alloys are often used for their lightweight properties, contributing to portability and user comfort. Diecast metal provides both structural integrity and thermal management capabilities, making it a crucial component in modern electronics.

Fact 4: Testing Diecast Metal Strength

The strength of diecast metal is rigorously tested to ensure it meets the necessary standards for its intended application. Various tests are used to evaluate the mechanical properties of the metal, including tensile, yield, and hardness tests. These tests provide critical data on the material’s ability to withstand stress, deformation, and wear. The testing methods and standards are essential for quality control and provide assurance that the diecast components will perform as expected. These tests help to identify potential weaknesses and optimize the manufacturing process to achieve the desired mechanical properties, leading to the production of reliable and durable parts.

Types of Strength Tests

Several tests are commonly used to assess the strength of diecast metal. Tensile tests determine the metal’s ability to withstand pulling forces. Yield strength tests assess the point at which the metal begins to deform permanently. Hardness tests, such as Brinell or Rockwell, measure the metal’s resistance to indentation. These tests provide a comprehensive understanding of the metal’s mechanical properties. Each test provides different insights into the material’s characteristics. These tests are critical for ensuring that the diecast components meet the design requirements and safety standards. The results provide essential data to engineers and manufacturers.

Standards and Specifications

Various industry standards and specifications govern the testing and quality of diecast metal. These standards, set by organizations like ASTM International and ISO, provide standardized test methods and performance criteria. Compliance with these standards ensures consistency and reliability across different manufacturers and applications. They also provide a benchmark for evaluating the mechanical properties of diecast materials. Adhering to these standards guarantees that diecast parts meet stringent quality and safety requirements. The use of standardized testing methods allows for meaningful comparisons and reliable performance predictions, critical for design and manufacturing.

Fact 5: Advantages and Limitations

Diecast metal offers several advantages that make it a preferred choice in many manufacturing applications. However, it also has some limitations that must be considered. Understanding these advantages and limitations is essential for selecting the most suitable material and manufacturing process for a particular application. Balancing these considerations ensures that diecast components are both cost-effective and perform as intended. Making an informed decision is critical to achieve optimal results in terms of performance, durability, and cost-effectiveness. Comprehensive knowledge of these aspects is crucial for effective design and manufacturing.

Advantages

The advantages of using diecast metal include high precision, complex shapes, and excellent surface finish. It allows for the production of intricate designs with tight tolerances, which is difficult to achieve with other manufacturing processes. The high production rates and cost-effectiveness, especially for large volumes, are significant benefits. Diecast components often have a good strength-to-weight ratio, making them suitable for various applications. Furthermore, the ability to cast different alloys allows for customization of the mechanical properties to meet specific needs. The advantages contribute to its wide adoption across several industries, allowing for mass production and durable products.

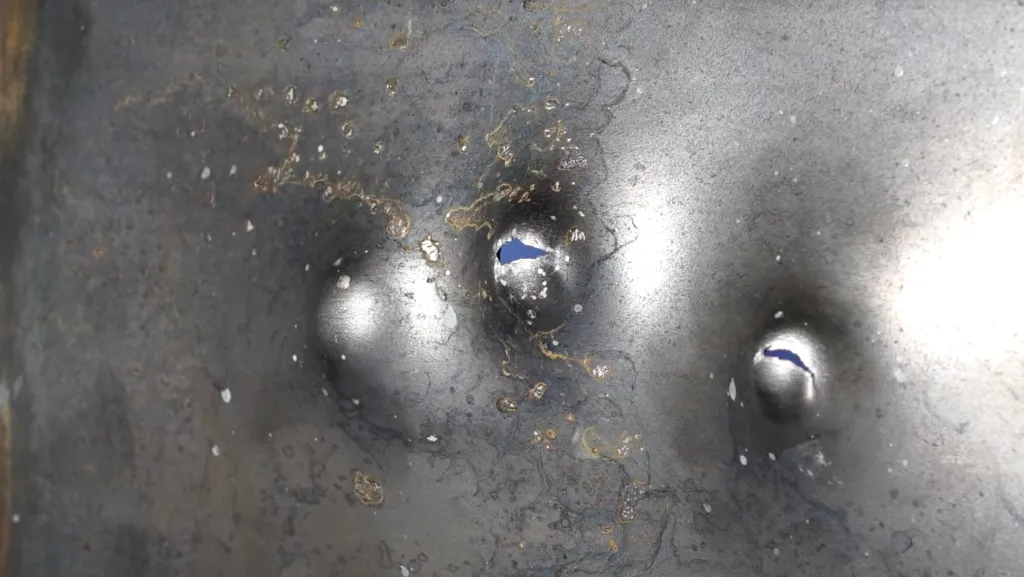

Limitations

Despite its many advantages, diecast metal also has some limitations. The initial cost of tooling can be high, making it less cost-effective for short production runs. Diecast parts may be subject to porosity, which can affect their strength and durability if not properly managed during the manufacturing process. Also, die casting is limited to metals with relatively low melting points. While advanced die casting can address these limitations, it’s essential to carefully evaluate the pros and cons before selecting die casting for a specific application. These limitations need to be considered during the design phase to guarantee the component’s functionality and longevity.